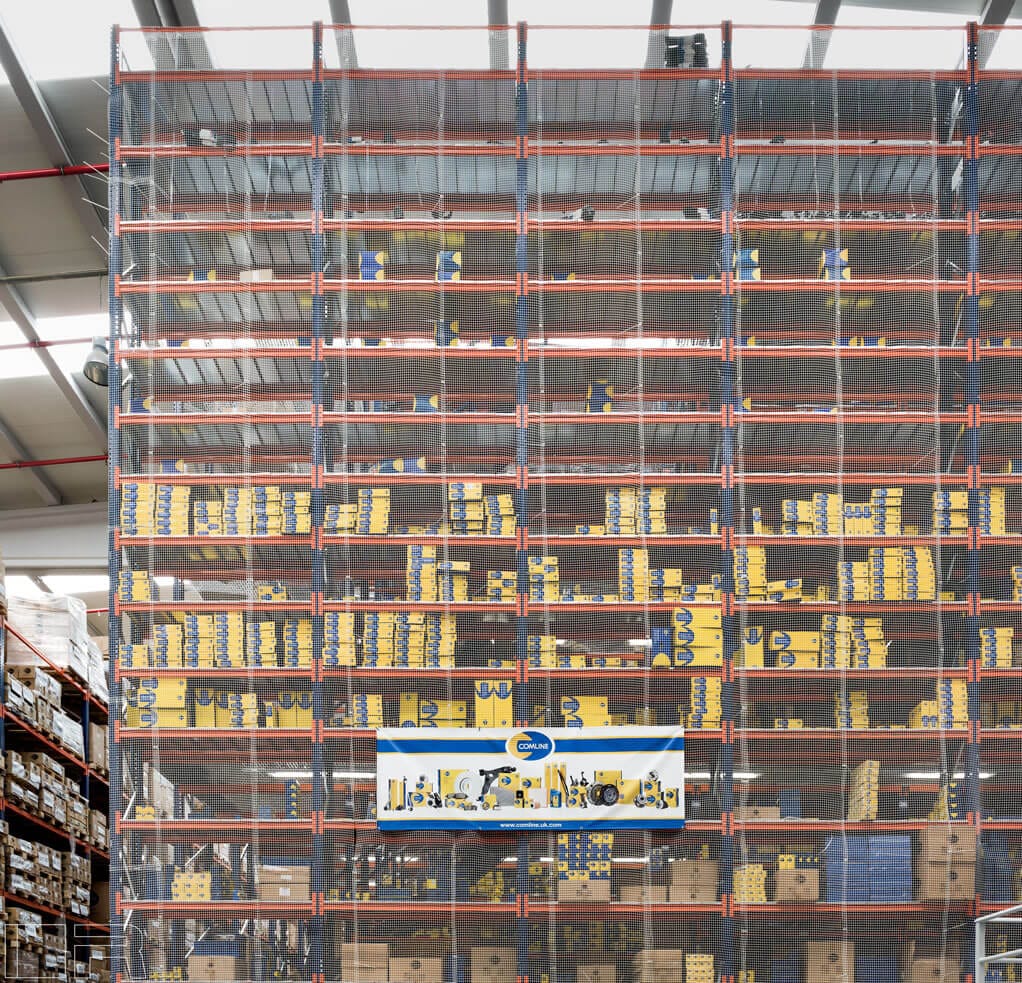

The use of a manual loading system with raised corridors is indicated when it is necessary to increase installation performance if the volume of the premises is sufficient and it is required for warehouse logistics.

It is commonly used in companies that process a large number of references of different shapes and medium and light loads handled using manual and individual access. Owing to the wide variety of parts and accessories and the extensive options for configuration and adaptation to particular uses, the system is suitable for the high-performance picking tasks required by specialist logistics companies and for managing large inventories commonly operated by industrial supply companies, hardware stores, spare parts warehouses and the car industry, etc.