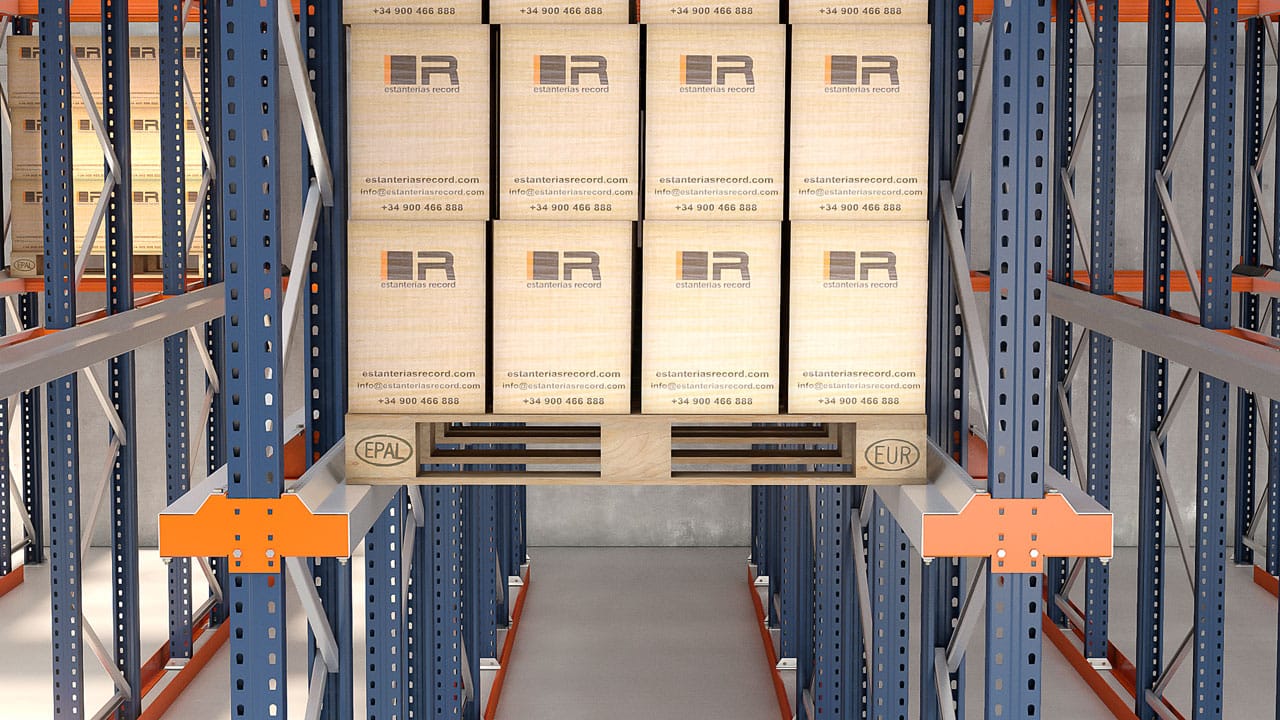

This system is ideal for managing goods with uniform dimensions, moderate rotation, a low obsolescence rate and a large number of pallets for each type of product.

It is the perfect solution for maximising the use of storage space and the system’s capacity by storing as many pallets as possible.

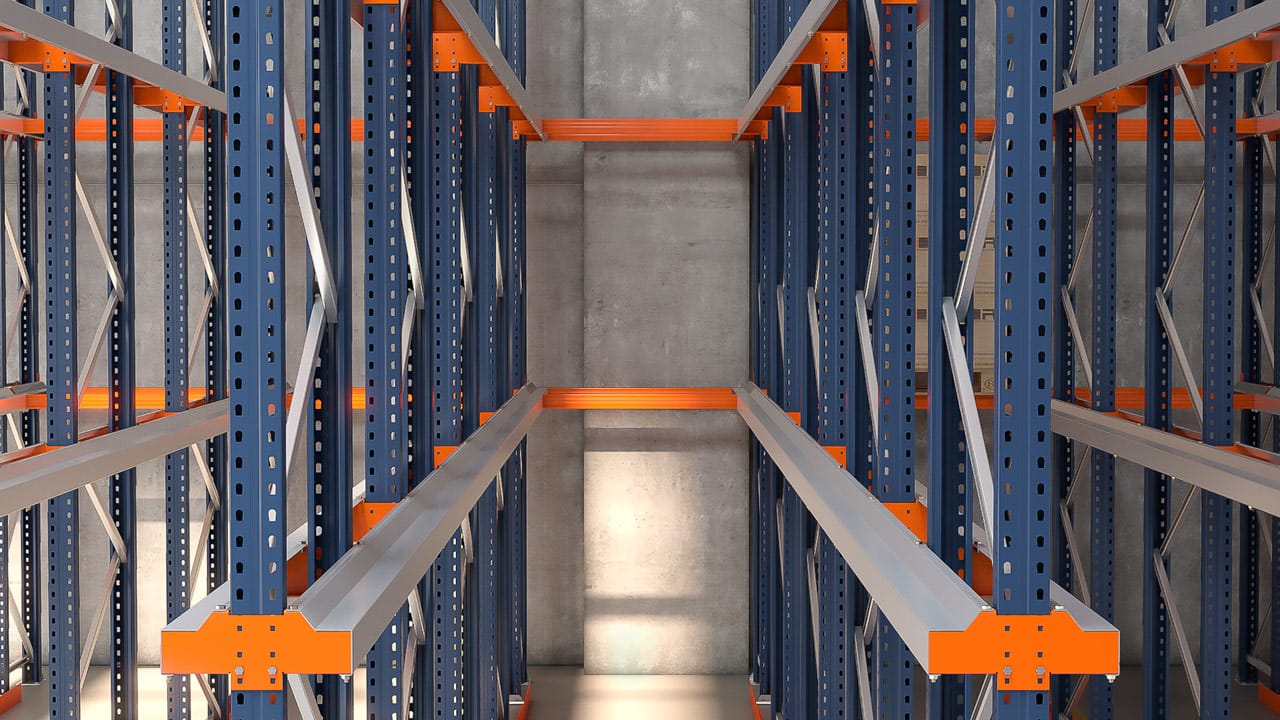

The design of the single entrance configurations is perfectly adapted to LIFO (last in first out) warehouse management systems. On the other hand, the double entrance installations are optimal for FIFO (first in first out) warehouse management procedures.

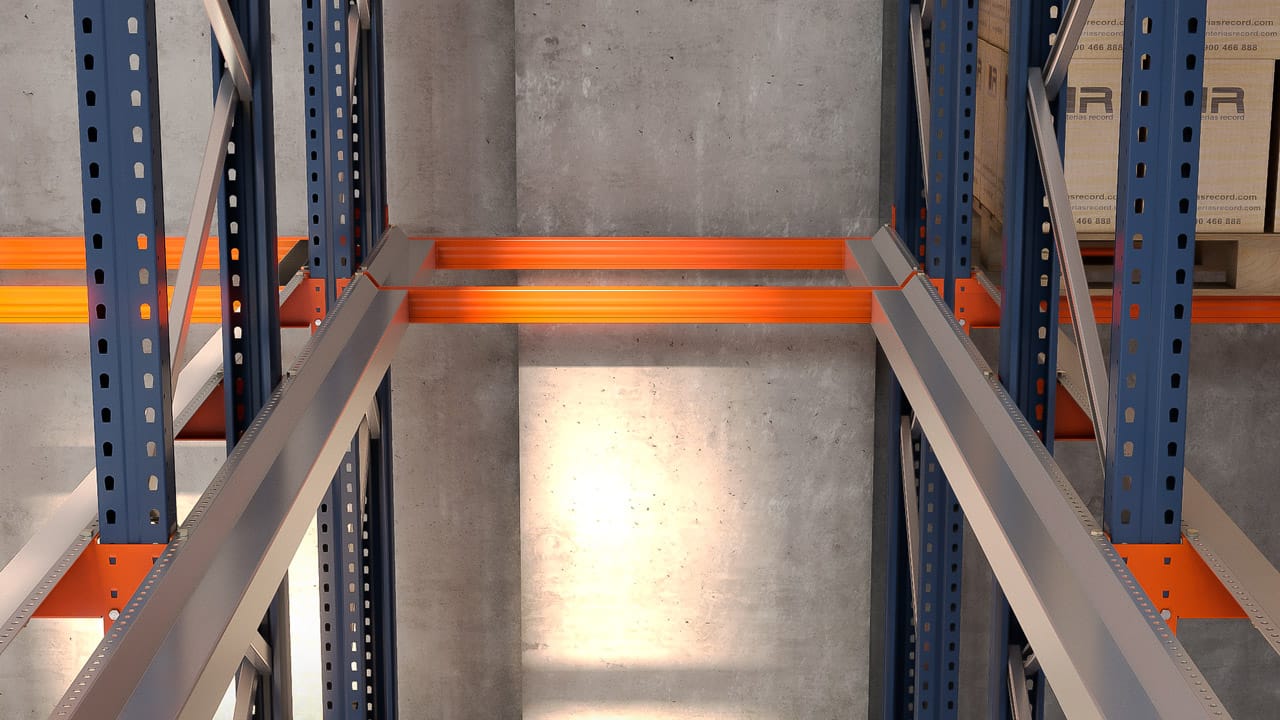

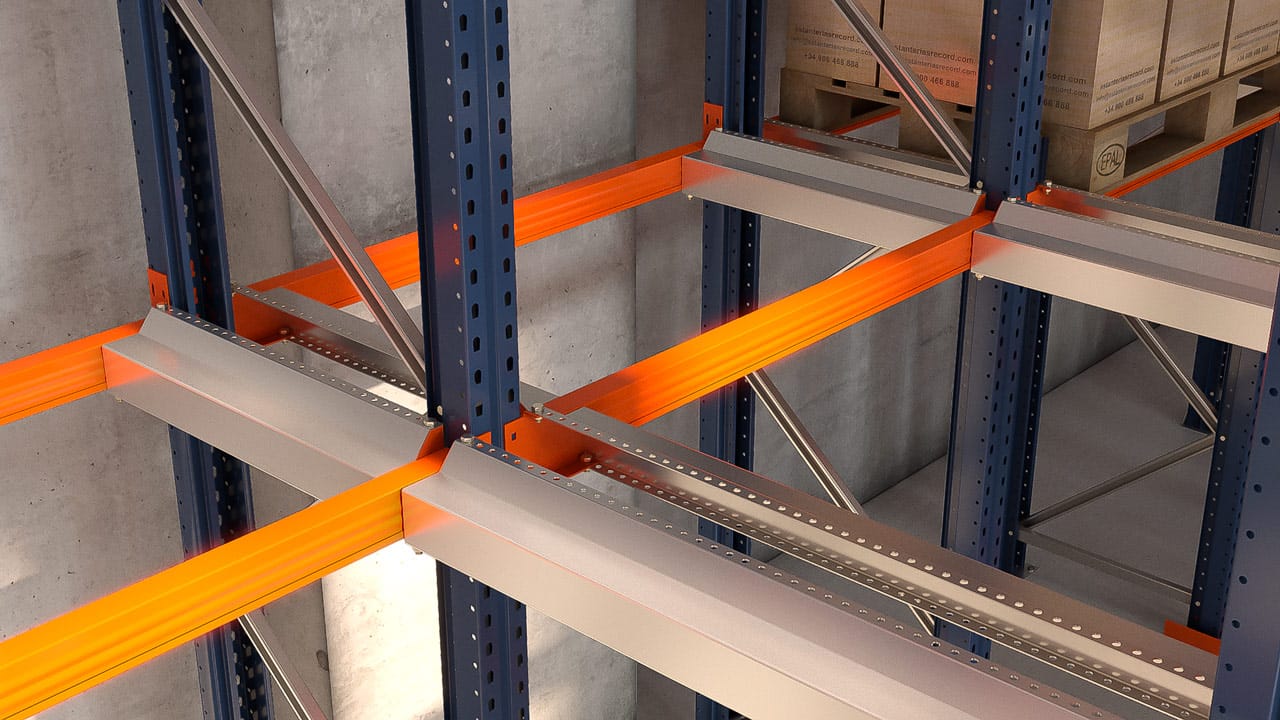

Compact pallet racking systems can be used with products of different shapes and weights since their structural components and the range of accessories available mean they can be modified to store a wide variety of goods.

Whatever the case may be, these systems are indicated for warehouses where rapid and selective pallet access is less important than overall system productivity and capacity.