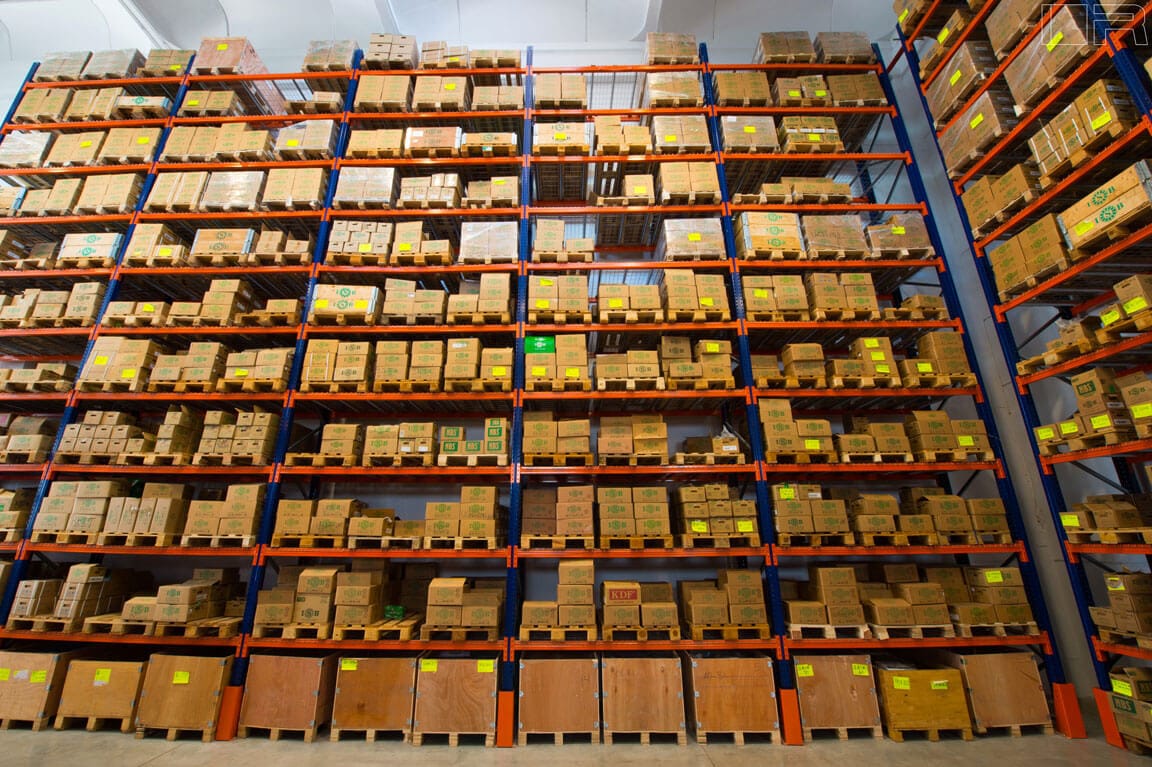

This system is ideal for storing all types of palletised heavy loads. Given the flexibility of design and a wide range of accessories and complements, the shelving can be and accessories, the racks can be configured to adapt to any use or product, whether by weight, size or morphology. product, whether by weight, size or morphology. Likewise, its components can be components can be adapted to allow the installation to house different types of merchandise, thus different types of merchandise, constituting a truly versatile solution to manage multi-customer or multi-product multi-customer or multi-product warehouses. Due to its design, the system is particularly suitable for warehouses with a large variety and quantity of items, and high levels of rotation and replenishment.

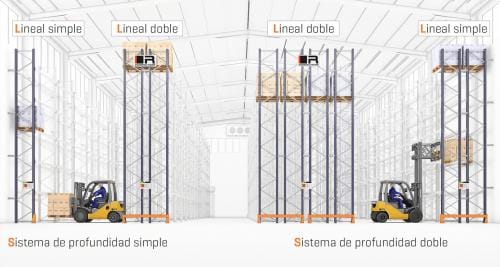

It is also the perfect choice for storing uniform products with several pallets for each type of product and a moderate obsolescence rate, since the installation of double-deep racking configurations compacts the loads and optimises the warehouse’s surface area.

The system can be configured for mixed usage, combining its function as a heavy pallet racking system with the storage of manually handled goods for direct picking operations.

In summary, it is a structural design concept for large loads that can be adapted to practically any requirements no matter how specific they may be.