The load-bearing capacity of a racking system is the maximum load it can support according to the theoretical calculation of its structural design. The maximum allowable load is the maximum authorised weight under conditions of use, which implies the consideration of safety margins and its value will always be lower than the theoretical load-bearing capacity. Since this second aspect is included in the calculation regulations and is systematically considered in projects carried out by Estanterías Record, we recommend identifying both concepts as equivalent in practice, if we want to study them from a safety perspective.

According to this approach, we must understand that the load-bearing capacity of a racking system is the result of considering many factors: its structural design, based on the applicable calculation standards, the materials used, the intended use and the characteristics of the logistics operation, the physical environment of the warehouse, integration with handling equipment, etc. At Estanterías Record each project is calculated following the established design procedures and the applicable European standards. This means considering not only the strength characteristics of the steels used and the specific configuration of the system components, but also other functional determinants involved in each particular implementation.

Understanding and observing the basic load limitation and system configuration parameters is essential to ensure the safety of staff, goods, the integrity of the structure and the efficiency of the warehouse. In this article we review the concepts of load capacity for industrial racking, the importance of complying with current regulations, the value of a custom design according to load requirements, and some good practices for use, maintenance and inspection that help keep the system in perfect condition.

How is racking load capacity calculated?

At Estanterías Record, the load capacity of each system is determined according to its technical specifications and conditions of use. Each model is calculated according to safety criteria to ensure optimal functioning. The nameplates contain safety guidelines and indicate the maximum weight per level, always considering an even distribution of the load. It is important to place the pallets centred on the beams and handle them properly to avoid deformation due to overloading and loss of load-bearing capacity.

In short, the maximum load of the racking system and its performance depend on its technical configuration and other physical and functional determinants of the project in question; therefore, each installation is designed in a completely individual way.

What happens if the load capacity of industrial racking is not observed?

Observing the racking load capacity is essential for warehouse safety. Overloading or poor weight distribution reduces system stability and significantly increases the risk of accidents. Any damage or deformation to the racking reduces its load-bearing capacity and jeopardises the consistency of the structure, which can lead to dangerous situations in logistics activities and result in possible material or personal damage. Exceeding the established load limits can cause structural failures or collapses with serious consequences.

Current regulations require that all racking systems clearly indicate their load limits and that these are observed. Each installation must have visible plates with the allowable load capacity and other technical specifications, as well as safe use guidelines. In addition, these nameplates must always be up to date according to the actual condition of the installation. Therefore, it is necessary to periodically check that the information they contain matches the current system configuration.

Custom design according to racking load requirements

Estanterías Record designs each system considering the customer’s load requirements as a key parameter; based on this, the appropriate structure components and their specific configuration are selected for each individual project to guarantee the safety standards established in the applicable regulations. If a warehouse needs to increase its capacity, all system elements must be recalculated to adjust the design.

As a preliminary step, Estanterías Record prepares a preliminary project detailing the proposed design according to the load requirements and other customer specifications.

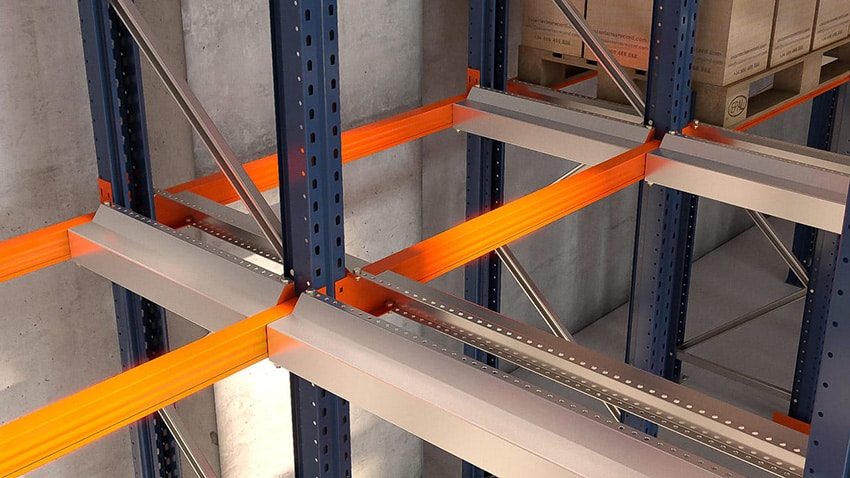

In addition, thanks to the variety of solutions available at Estanterías Record, it is possible to choose the most suitable storage system according to the type of goods and the usage requirements. Thus, for heavy loads handled by mechanical means, we highlight systems such as conventional pallet racking, compact drive-in pallet racking, pallet racking with picking levels, mezzanines over pallet racking, mezzanine floors, cantilever racking systems or reel-holder rack. In the case of medium loads managed manually, we opt for a conventional picking rack system , picking rack over floor, mezzanines over manual loading, hanging racks, tyre racks or the Bricord rack, SINcord Basic and SINcord Plus+ models.

Estanterías Record guarantees an optimal, safe design adapted to each storage need, always offering the best combination of capacity, functionality and durability.

Good practices: use, maintenance and regular inspection

To maintain the load-bearing capacity of the racking systems and their safe use, it is recommended to follow a set of good operational practices:

Check the nameplates and technical data. It must be ensured that the load-bearing capacity plates are placed in visible locations and match the actual installation. All workers must be trained to interpret these data correctly.

Do not modify the installation without authorisation. Under no circumstances should the original configuration (number of beams, levels, distribution, bracings, unit loads, etc.) be changed without consulting Estanterías Record, so that the maximum load capacity can be recalculated. Any alteration, no matter how small, can affect structural sizing.

Do not overload. The maximum load of the system must not be exceeded under any circumstances, as a result of incorrect distribution of the goods or improper work practices with handling equipment.

Regular inspections. A regular maintenance and inspection programme must be followed according to regulations to ensure the proper functioning of the system. Estanterías Record has a Technical Inspection (ITR) service that analyses the physical and functional condition of the racking and assesses its damage. These technical inspections, together with proper staff training, help detect risk situations before they can compromise the load-bearing capacity of the structure.

Continuous maintenance. Intensive or improper use causes the deterioration of racking components and can reduce its stability. Therefore, it is recommended to replace damaged parts according to a regular maintenance plan.

Responsible use. Storage equipment must always be used according to the specifications for which it was designed, using the unit loads and mechanical handling equipment provided, to ensure that the working clearances considered in the project are observed and risks are minimised in load handling operations.

Estanterías Record provides each of its customers with detailed technical documentation on their installation, as well as the necessary after-sales support to help them manage their storage system correctly. These measures contribute to efficient and safe management of the installed equipment, in line with best industry practices.