Sustainability in the supply chain is a crucial issue in today’s world, where environmental and social challenges demand a change in the way we manage resources.

Storage decisions, often underestimated, have a significant impact on the environment, from the use of materials to energy consumption.

Product storage can have negative impacts, such as the excessive use of non-recyclable materials, high energy consumption and waste generation. For example, single-use plastics remain a critical problem, while inefficient energy management in warehouses contributes to greenhouse gas emissions.

Adopting sustainable practices, such as the use of biodegradable materials and energy-efficient technologies, is essential to mitigate these effects.

Benefits of the sustainability in the supply chain

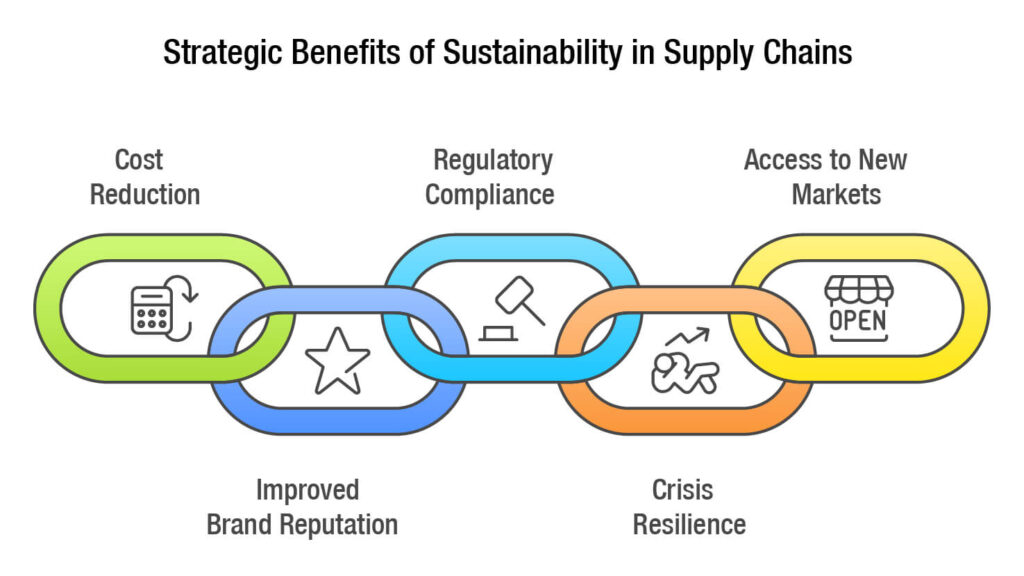

Sustainability in the supply chain not only benefits the environment, but also brings economic and reputational benefits to the company:

- Reduction in operating costs: Resource optimisation, efficient use of materials and waste reduction can significantly reduce operating costs.

- Improved brand reputation: Companies that adopt sustainable practices strengthen their corporate image, attracting customers and investors who value environmental and social responsibility.

- Regulatory compliance: Implementing sustainable practices helps companies comply with environmental and social regulations, avoiding penalties and improving their position in the market.

- Crisis resilience: Sustainable supply chains are more resilient to disruptions, such as natural disasters or economic crises, thanks to their focus on responsible management and the use of renewable resources.

- Access to new markets and innovation: Sustainability fosters research and development of innovative solutions, opening up opportunities in markets that prioritise responsible practices.

Challenges

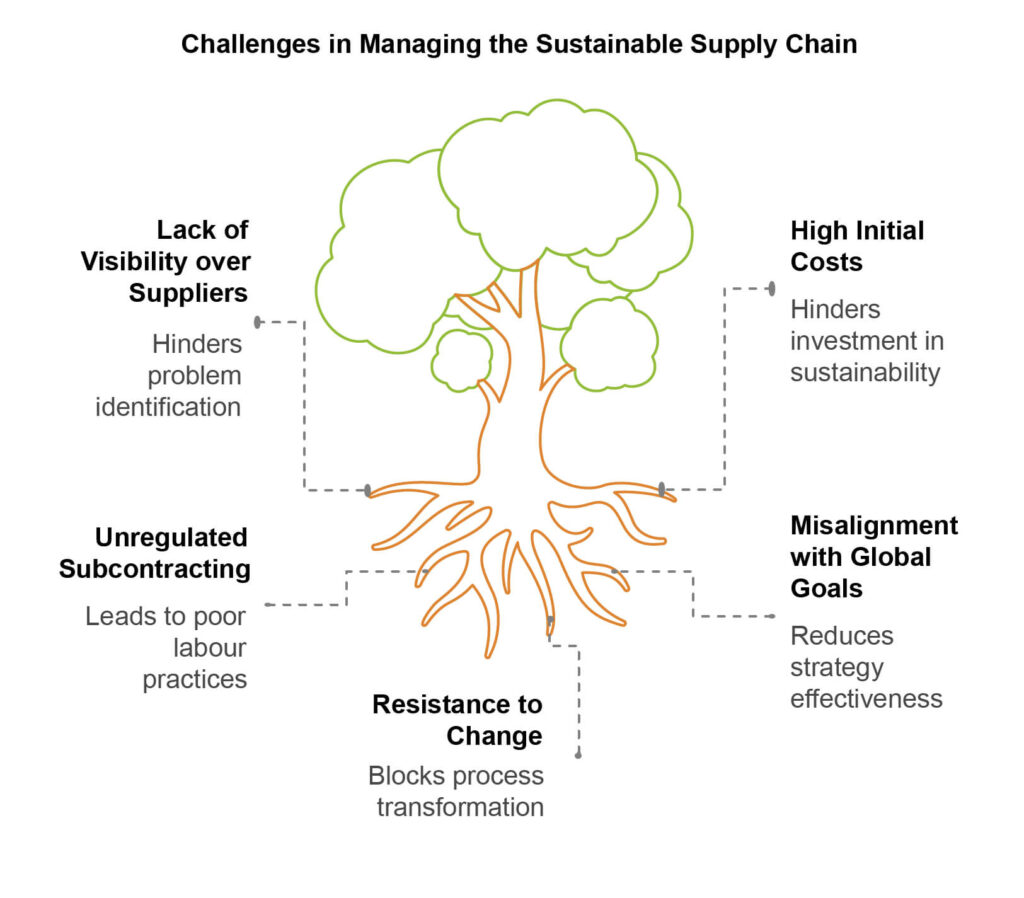

Sustainability in the supply chain is not without challenges, such as those detailed below:

- Lack of visibility over suppliers: Many companies have no overview of their suppliers’ sustainability performance, especially in complex supply chains. This makes it difficult to identify problems and implement effective improvements.

- High initial costs: Implementing sustainable technologies and practices requires a significant initial investment, which can be an obstacle for many companies.

- Subcontracting and lack of oversight: Unregulated subcontracting can lead to inadequate labour and environmental practices, especially in regions with less stringent regulations.

- Alignment with global goals: Many companies fail to align their sustainability goals with international standards, such as those established by the IPCC, which reduces the effectiveness of their strategies.

- Resistance to change: Companies face cultural and organisational challenges when trying to change established processes to more sustainable models.

Although the challenges are significant, the solutions are within reach: from the adoption of clean technologies to collaboration with suppliers and customers.

Comprehensive Approach

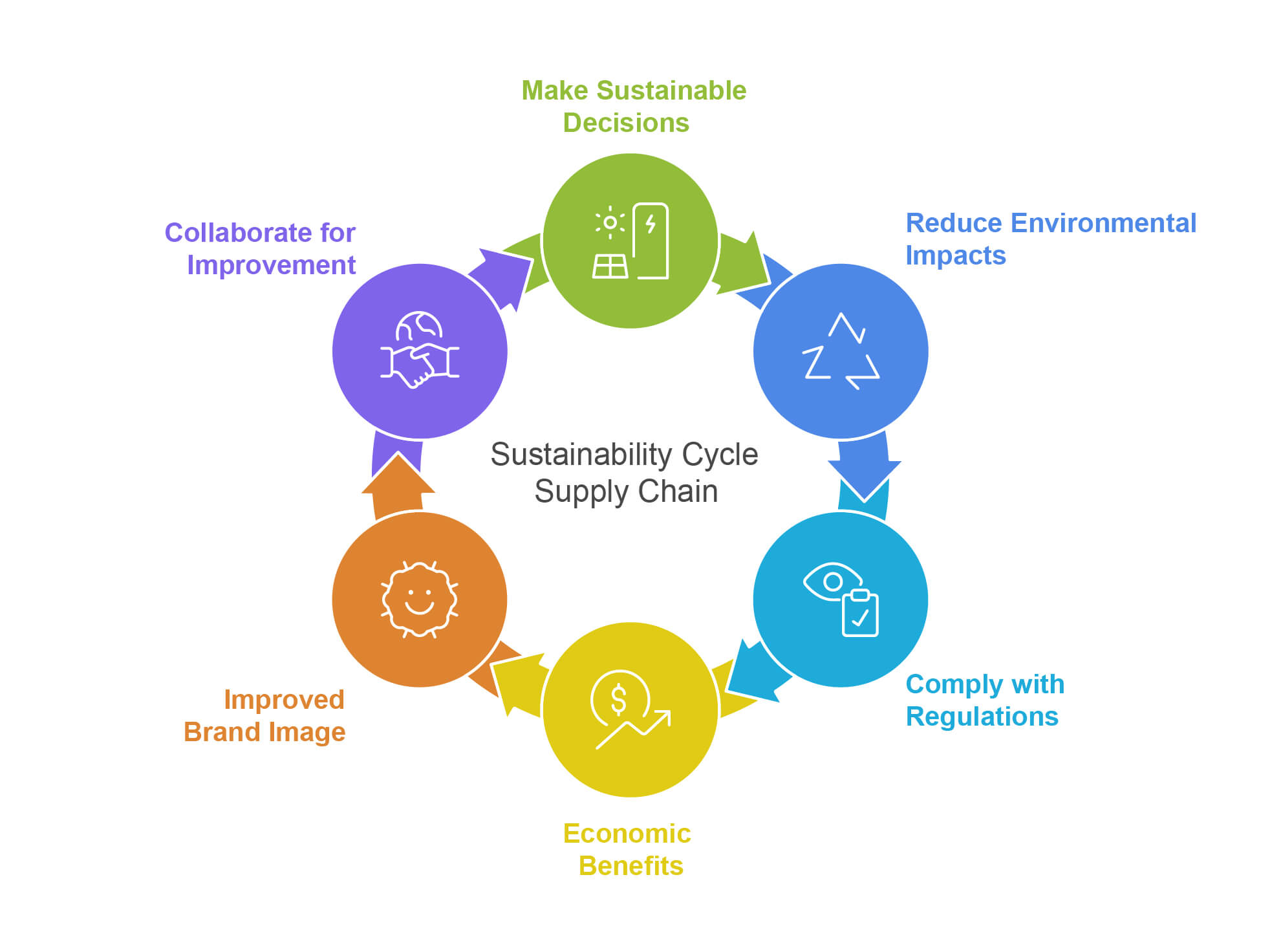

Sustainability in the supply chain requires a comprehensive approach that covers everything from the sourcing of raw materials to waste management, including strategic agreements with stakeholders involved in the chain.

This involves reducing carbon emissions, optimising resource use and ensuring fair working conditions.

An example of this approach is collaboration with auditing firms, which verify compliance with environmental and social standards. These audits help identify areas for improvement and ensure transparency at all stages of the chain.

Sustainability in the supply chain is not just a responsibility, but an opportunity for companies to lead the change towards a more ethical and environmentally friendly future, and to ensure their competitiveness in an increasingly demanding market.