In the dynamic world of warehousing and logistics, pallets are essential elements in the supply chain.

There are various types of pallets, each with specific characteristics that adapt to different needs and sectors.

Knowing the type of pallet used in a warehouse is vital for designing and implementing the optimal pallet rack system in each case.

Below is a summary of the different types of pallets based on materials and design, their measurements and dimensions, as well as their characteristics, uses and functionalities.

Pallet classification: diversity to choose the best option

Pallet classification is mainly based on two key criteria: the manufacturing material and the structural design. Knowing these categories is the first step in selecting the right pallet for each storage need in your industrial racking.

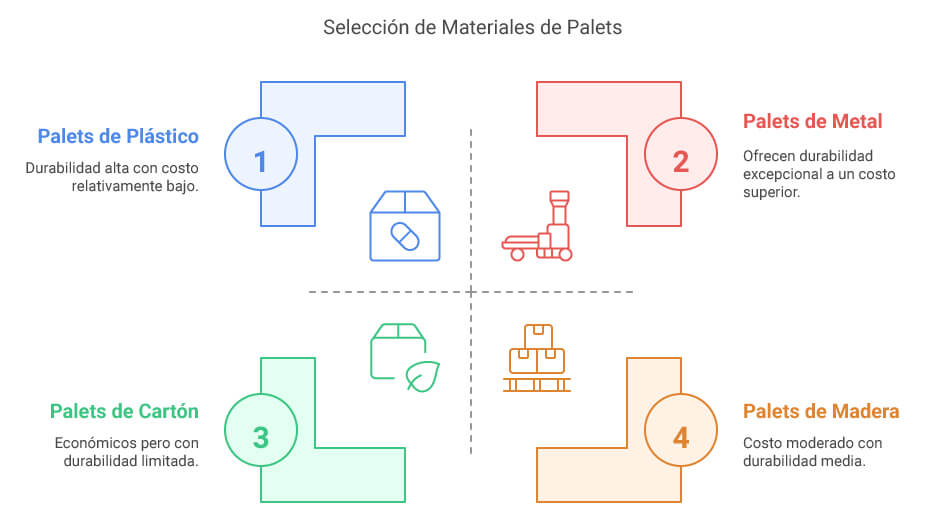

Types of pallets by material: adaptability to each environment

The choice of pallet material directly impacts its strength, durability, hygiene and cost.

- Wooden Pallets. The most common and recognised in the industry, noted for their strength and load capacity. Their ability to be repaired and reused contributes to their popularity and sustainability. They are ideal for general logistics due to their versatility and load capacity.

- Plastic Pallets. They are gaining ground for their durability and ease of cleaning. They are resistant to pests and moisture, making them an excellent choice for the food and pharmaceutical industries. Furthermore, they do not require additional treatments for export. They offer superior resistance to adverse conditions such as moisture and chemicals.

- Cardboard Pallets. Generally disposable and designed for single use, they are especially useful in sectors where hygiene is crucial, such as food. Their light weight makes them practical for certain applications, being a cost-effective and efficient option for dry and clean environments.

- Metal Pallets. Typically made of steel or aluminium, they offer exceptional strength, ideal for heavy loads and demanding environments. Although their cost is higher, their durability offsets the long-term investment. They are also used in sectors with rigorous hygiene standards.

- Wood Fibre Pallets: Made of wood chips and resins, they represent an ecological and lightweight alternative. Their ability to be recycled and reduced transport costs make them attractive.

Types of pallets by design and measurements: standards and specific solutions

The design of the pallet is crucial for its compatibility with storage and transport systems.

- European Pallet (Europallet): the standard in Europe, with dimensions of 1200 mm x 800 mm. Its regulation through EPAL ensures uniformity and quality, allowing its use in multiple industries.

- American Pallet: with dimensions of 1200 mm x 1000 mm, is the most widely used in the United States. Its robust design allows it to withstand significant loads, being key in the logistics of that country.

- Other Types of Pallets: there are specific designs for particular needs, such as the CP pallet in the chemical industry, varying in size and characteristics. We also find the half Euro pallet (800 mm x 600 mm) ideal for smaller loads and the quarter pallet (600 mm x 400 mm) perfect for shelf displays.

The measurements and dimensions of pallets are key aspects for optimising space in warehouses and facilitating load handling. Knowing these specifications enables effective use of metal shelving systems. Choosing the right size can significantly improve operational efficiency.

Uses and Functionalities: beyond simple transport

Pallets are widely used in storage and distribution, favouring the proper handling of palletised goods and allowing the optimisation of space both vertically and horizontally in storage systems.

In transport and export, pallets provide a stable base that protects the goods against damage. They also comply with international transport regulations.

In specific sectors such as retail, the pallet is also used for product display, facilitating restocking tasks on rows.

Advanced Functionalities: technological integration in storage

Modern pallets integrate with storage technologies, such as automated picking systems and RFID technology, allowing for more precise and real-time inventory management. This technological integration increases productivity and improves the organisation and control of stored products.

Choosing the right pallets results in cost savings in the supply chain, optimising transport processes and reducing operational expenses.

More durable and versatile pallets offer a better long-term return on investment, being a determining factor for the financial sustainability of the company.

Understanding the diversity and functionalities of pallets is essential for any company looking to optimise its storage operations with efficient industrial metal shelving adapted to its needs. The correct choice of pallet, together with an appropriate shelving system, will maximise space, improve logistical efficiency and contribute to the overall success of your business.