Storage equipment and systems are designed to have a long useful life, provided they are properly maintained. During this time, the circumstances that affect operation can significantly alter both functionality and performance, impacting safety and hazard prevention and thus needing proper assessment and management.

Uses other than those considered in the original design, changes of location, alterations in the configuration or structure of the system, modifications to components, repairs and replacements of parts, damages not repaired, use of handling equipment or loading units not adapted to the initial specifications or simply changes in the physical or environmental surroundings of the storage system will directly affect performance, integrity and capacity. This may lead to situations of significant risk and compromise the safety of people and property.

It is therefore necessary to systematise procedures for updating and reviewing these possible scenarios in order to guarantee the safety standards required by current legislation and regulations.

Royal Decree 1215/1997, which establishes the minimum health and safety provisions for the use of work equipment by workers, considers storage facilities and systems as such and, therefore, all the specific mandatory legislative guidelines on safety and hazard prevention apply.

Furthermore, given that the performance and safety of storage systems depend largely on installation and service conditions, the precepts given in Article 4 of the aforementioned Royal Decree must be observed, where said Royal Decree establishes the obligation for an initial check after installation and before the first commissioning, together with an additional check each time there are transformations or situations of structural or functional change that may affect safety.

It also provides that work equipment subjected to influences likely to cause deterioration and, consequently, hazardous situations must be checked periodically and any damage promptly repaired.

The fact that the Royal Decree provides that, “The requirements and conditions for checking work equipment shall be in accordance with the specific regulations applicable thereto” (Article 4, section 5) opens up two cases in this regard:

When there are situations of change throughout the useful life of the system that affect its behaviour and performance, the specific standard is UNE 58014. Steel static storage systems. Validation of storage systems, which establishes the scenarios in which each type of check must be carried out for the mandatory system validation certificate and authorisation for use.

When it comes to the periodic checks necessary to properly maintain the storage system, preventing hazards and ensuring that its capacity is not diminished by deterioration during use, the specific standard is UNE-EN 15635 Steel static storage systems. Use and maintenance of storage systems, which establishes maintenance guidelines for the systems and determines the need for at least one annual inspection by technically skilled personnel.

For the correct application of both standards, it is essential to observe the other standards to which they refer and which reflect the current state of the art:

UNE 58013, Steel static storage systems. Requirements for the treatment of damaged parts.

UNE 58015, Steel static storage systems. Mezzanine on pillars. Principles for structural design.

UNE 58016, Steel static storage systems. Storage system for satellite trolley. Principles for structural design. Tolerances, deformations and clearances.

UNE 15512, Steel static storage systems. Adjustable systems for palletised loads. Principles applicable to the calculation of structures.

UNE 15620, Steel static storage systems. Adjustable storage systems for palletised loads. Tolerances, deformations and clearances.

UNE 15629, Steel static storage systems. Storage system specifications.

UNE-EN 15878, Steel static storage systems. Terms and definitions.

Technical Prevention Note TPN 852, Steel static storage systems, from the National Institute for Occupational Health and Safety.

The main aim of the regulatory framework described above is to minimise hazards inherent to the use of storage systems and ensure safe operation of the warehouse.

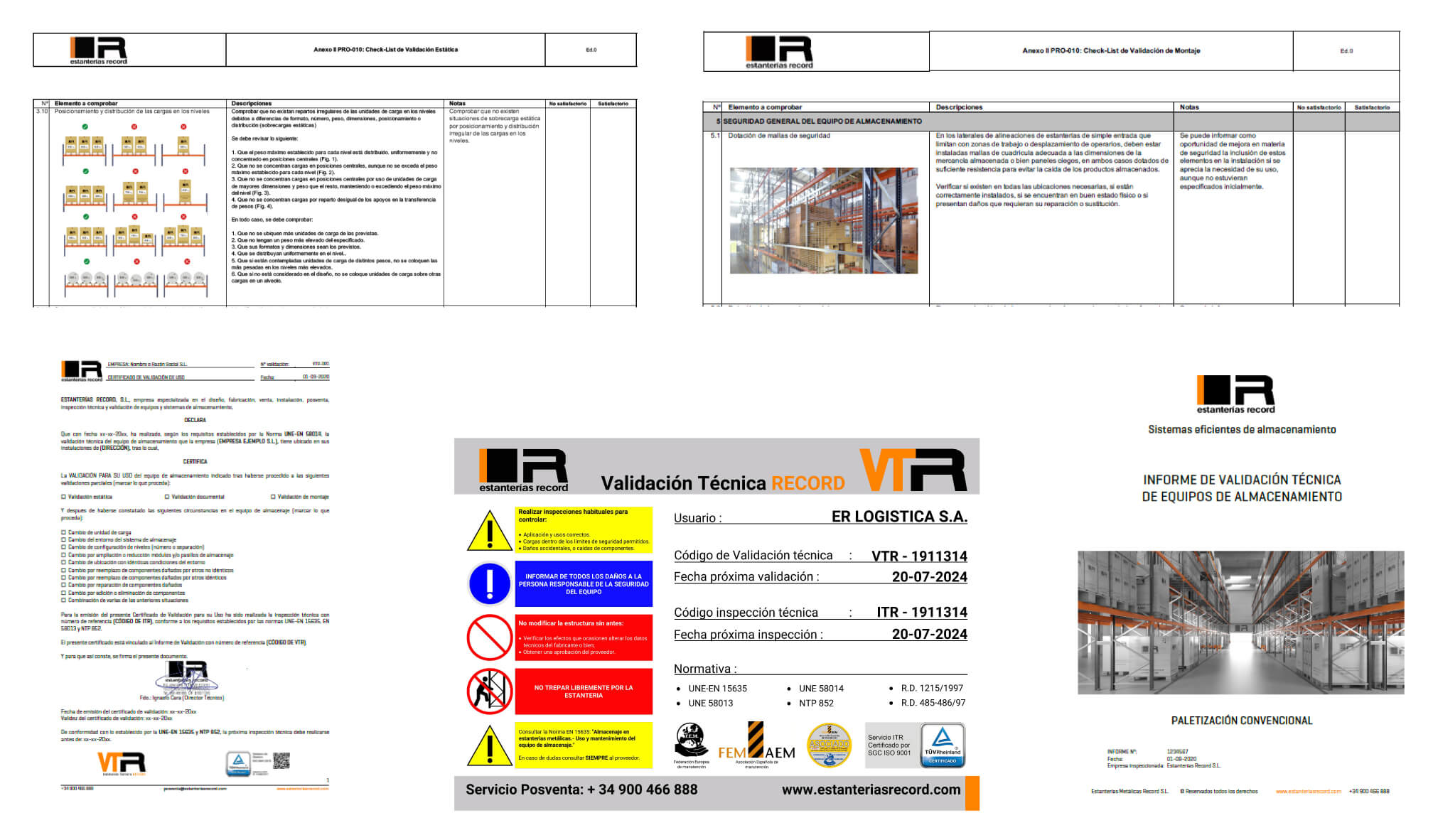

The UNE 58014 standard. Steel static storage systems. The validation of the storage system establishes a clear methodology to accurately define and classify the system throughout its useful life and, consequently, the process to be followed to certify validation for use.

Said validation comprises global certification by an authorised technical expert for the safe use of the storage system after checking compliance with the corresponding partial validations (static, documentary and assembly) and an annual technical inspection if necessary, depending on each specific situation.

As value-added for the validation service, Estanterías Record performs a rigorous preliminary Technical Inspection in all cases in accordance with the UNE-EN 15635 standard. Said preliminary inspection applies ITR’s own methodology as accredited by the ISO 9001 quality assurance system certification awarded to the company and which covers the design, manufacture, sale, installation, after-sales and technical inspection and validation services of shelving and other storage systems.

Once the ITR Technical Inspection is complete, the authorised expert shall assess the findings identified during the inspection that are relevant for passing the partial validations (static, documentary and assembly) prior to the global validation of use. If said assessment is satisfactory, the system will be validated for use and the corresponding accreditation certificate will be issued.

In the event of incidents affecting the inspected items, corrective actions will be proposed and, if necessary, a subsequent check performed to verify the corrections made. Once the process has been completed satisfactorily, the certificate of validation of use will be issued.

The process described above is implemented as required with full, detailed documentary support provided to the customer.

In accordance with regulatory requirements, Estanterías Record’s authorised technicians have:

The necessary qualifications, training and experience, as well as sufficient knowledge of the requirements for the validations performed.

The ability to give professional opinions on conformity with general requirements based on an examination of results and to report accordingly.

Sufficient knowledge of the technology used in the design and manufacture of the products under inspection, the way in which the system or processes subject to the inspections are used and the defects that may appear during their use or service.

The ability to understand the significance of any deviations found with regard to the normal use of the system or processes in question.

Duly inspected and validated systems offer customers important direct benefits for their business. These include:

Increased warehouse safety. This results in more cost-effective management of resources and avoids potential exposure to civil or criminal proceedings for claims that can be avoided.

Improved hazard prevention and productivity. The reduction of incidents invariably increases the return on investment and, consequently, the profitability of the business.

Compliance with legislation. Complying with mandatory legislation avoids administrative litigation and shows an internal commitment and rigour vis-à-vis third parties.

Administration of assets. The increase in asset performance and the higher level of asset protection leads to better asset management in terms of insurance costs, damage valuation, liability coverage with insurers, public administrations and private entities, etc.

Corporate image. The above improves the perception and global image of the company vis-à-vis customers, collaborators, investors and shareholders, etc.

When should I perform a Technical Validation on my storage system?

After installing and before commissioning a new storage system. Additional validation is also mandatory after transformations or structural or functional changes.What legislation do I have to comply with?

Royal Decree 1215/1997, which establishes the minimum health and safety requirements for the use of work equipment by workers, and the UNE 58014 standard, Steel static storage systems. Validation of storage systems, and the UNE-EN 15635 standard, Steel static storage systems. Application and maintenance of the storage system.Who can perform the Technical Validation?

Technical Validations must be carried out by an authorised Technical Team. Trust in Estanterías Record’s experience.Will the validation process affect my logistic activities?

Our inspectors will examine your facilities without interfering with your daily logistics.What documentation certifies the validation of my storage system?

After passing the Technical Validation, Estanterías Record will provide you with full, detailed documentation of the process and the corresponding accreditation certificate.Do I have to renew the Validation of my warehouse?

The duration of the validation will be determined based on circumstances that affect the storage system and will be subject to its correct use, maintenance and inspection. In any case, the validation must be renewed in the event of modifications that affect the original structure or operation of the system.How can I request the validation service?

You can contact Estanterías Record on the toll-free number 900 466 888 or through the following link.